Industrial Rotary Disc Filter Center Shaft

Product Details:

- Product Type Rotary Disc Filter Center Shaft

- Material SS304 or SS316L

- Surface Treatment Coated

- Color Silver

- Click to View more

Industrial Rotary Disc Filter Center Shaft Price And Quantity

- 1 Set

- 10000-200000 USD ($)/Set

Industrial Rotary Disc Filter Center Shaft Product Specifications

- Rotary Disc Filter Center Shaft

- Silver

- Coated

- SS304 or SS316L

Industrial Rotary Disc Filter Center Shaft Trade Information

- Ningbo

- Letter of Credit (L/C) Telegraphic Transfer (T/T) Cash Advance (CA)

- 20 Set Per Year

- 4 Months

- Packed in FR and HQ

- North America South America Central America Asia

- All India

Product Description

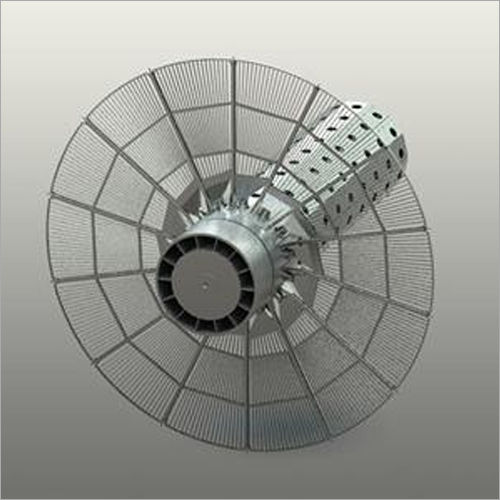

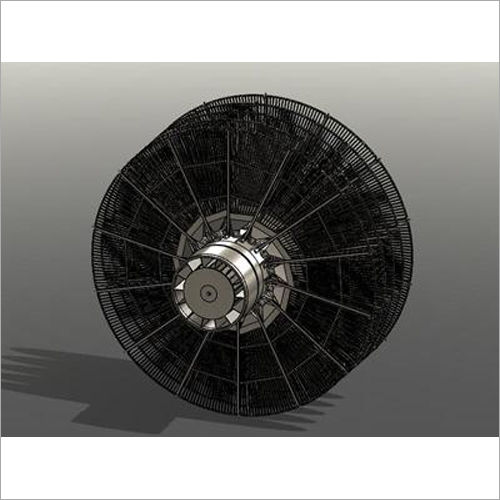

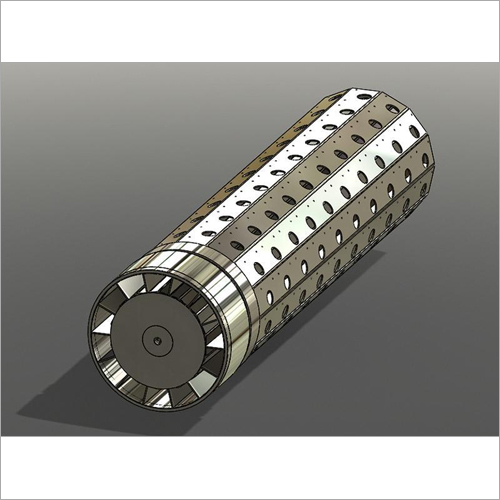

Center shafts are the core component to a rotary disc filter, and are used to allow the filtrate to flow through the filter. Hengtai s center shaft is put together by assembling all sectors through the notches on the hollow center shaft.

Our company usually uses center shafts made of SS304 or SS316L materials, though other materials can be used according to customer requirements. Our paper mill customers have successfully replaced their cast iron center shafts with stainless steel center shafts.

In general, those center shafts that are made of cast iron or carbon steel become easily corroded when exposed to acidic or alkaline chemicals, thus requiring frequent maintenance. In order to prevent that problem from arising, Hengtai uses a stainless steel center shaft with all filtrate tubes or notches sealed and welded to ensure their smoothness.

In addition to the improvements to the center shaft material, we have also redesigned the center shaft structure. The drainage channel uses an inclined angle, which reduces friction in the drainage channels, and increases the filtrate flow rate. This increases the flow ratio for the filtrate and the super clear filtrate, thus ensuring the stability of the rotary disc filter vacuum, increases the yield, and reduces the filtrate SS level.

Payment Terms,30 Percent payment in advance,balance paid by TT or LC

Main Export Markets: Sourtheast Asia,Russia,Egypt

Main Domestic Market: all domestic paper mills.

Other Products in 'Rotary Disc Filter Center Shaft' category

|

ZHEJIANG HENGTAI FILTERING EQUIPMENT CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |